ShareCRM is exhibiting at FABTECH 2025! Claim your free Expo Pass with promo code FBGUEST and visit us at Booth D37225. You can even schedule a personalized product demo in advance with our CRM experts to see how ShareCRM transforms field service for manufacturers.

As the Vice President of Revenue and Operations at ShareCRM, I spend a lot of time speaking with manufacturing service leaders who are facing many of the same challenges. The industry is at a pivotal moment, and artificial intelligence (AI) has changed how leaders are thinking about their business transformation. While production floors have incorporated AI into their processes, becoming increasingly more automated and connected, many field service operations remain stuck in reactive, manual processes that drain profitability and frustrate customers. This disconnect between advanced manufacturing capabilities and outdated service delivery models is creating both challenges and unprecedented opportunities for forward-thinking manufacturers.

The Evolution of Manufacturing Service Expectations

Today's manufacturing customers expect service experiences that match the sophistication of the products they purchase. When a $500,000 CNC machine goes down, customers don't just want it fixed—they want to know why it failed, when the next potential issue might occur, and how to prevent similar problems across their entire fleet going forward.

This shift from "break-fix" to "predict-prevent" service models isn't just a customer preference, it's becoming a competitive necessity driven by AI's transformative capabilities. Manufacturers who can deliver AI-powered predictive, proactive service experiences are winning longer-term contracts, achieving higher customer satisfaction scores, and commanding premium pricing for their service offerings.

The Hidden Costs of Reactive Service Operations

Most manufacturing companies underestimate the true cost of reactive field service operations. Beyond the obvious expenses of emergency dispatch calls and overtime technician hours, reactive service models create cascading inefficiencies throughout the organization:

Operational Inefficiencies

Manual Scheduling Bottlenecks: Traditional scheduling systems rely on dispatchers making assignment decisions based on incomplete information. This leads to suboptimal routing, technician skill mismatches, and extended customer downtime. According to a study by Vorcol, optimized scheduling can improve technician productivity by 15-25%.

Information Silos: When field service data lives separately from sales, inventory, and customer relationship systems, every stakeholder works with incomplete information. Sales teams can't see service history when discussing renewals. Service managers can't identify patterns that might prevent future failures. Parts departments operate reactively instead of predictively.

Mobile Productivity Gaps: Many field service teams still rely on paper-based processes. When technicians spend 30-40% of their time on administrative tasks instead of actual service work, labor costs skyrocket while customer satisfaction plummets.

Customer Experience Impact

Extended Downtime: Reactive service models inherently mean longer resolution times. Equipment failures that could have been predicted and prevented during scheduled maintenance become emergency situations that require parts ordering, technician travel, and complex diagnostics.

Inconsistent Service Quality: Without access to comprehensive equipment history, maintenance recommendations, and previous solution patterns, different technicians may approach identical problems in completely different ways, creating inconsistent customer experiences.

Limited Visibility: Customers increasingly expect real-time updates on service request status, technician arrival times, and resolution progress. Legacy systems simply can't provide this level of transparency.

Real-World Transformation: A Case Study

Consider the experience of a global LED display equipment manufacturer that transformed their field service operations. They experienced challenges similar to many manufacturers:

- Siloed Customer Information: Sales teams had no visibility into service issues that might affect renewal negotiations

- No Channel Management Solution: Complex dealer and distributor relationships weren't properly coordinated

- Fragmented Lead-to-Cash Process: Customer journey data was scattered across multiple systems

They implemented an integrated, AI-powered field service platform that connected sales, service, and marketing operations, which resulted in a:

- 30% Improvement in SLA Performance: AI-powered predictive maintenance and machine learning-optimized scheduling reduced customer downtime by anticipating failures before they occur.

- 30-Second Online Service Response: AI chatbots and automated intelligent systems provide customers with real-time service status updates and predictive maintenance recommendations.

- 1-Day Onboarding Process: AI-guided mobile workflows and smart knowledge systems enable new technicians to become productive immediately with contextual, step-by-step assistance.

- 20% Product Revenue Increase: AI-driven service analytics and predictive insights help sales teams identify precise upsell opportunities and improve renewal rates through data-backed customer health scoring.

Key Features of Next-Generation Field Service Platforms

Similar to this manufacturer, companies evaluating their current processes should prioritize platforms that deliver:

Predictive Service Capabilities

Use real-time data and AI to identify and resolve potential issues before they impact customers. This includes:

- Equipment health monitoring and predictive failure analysis.

- Automated work order generation for preventive maintenance.

- Parts demand forecasting to ensure inventory availability.

Mobile-Optimized Technician Experience

Field service reps need tools that make their jobs easier, not harder:

- Complete Work Order Management: From accepting assignments to capturing completion data, everything should be manageable from a mobile device.

- Instant Access to Information: Equipment history, technical documentation, parts availability, and customer communication should be immediately accessible.

- AI-Powered Support: Knowledge bases that can instantly recognize problems and recommend solutions.

Connected Operations

Integration between sales, service, marketing, and partner operations:

- Customer 360 Views: Complete visibility into customer relationships across all touch points.

- Partner Relationship Management: Coordination between direct sales teams and dealer/distributor networks.

- Connected Lifecycle Management: Equipment tracking from initial sale through ongoing service.

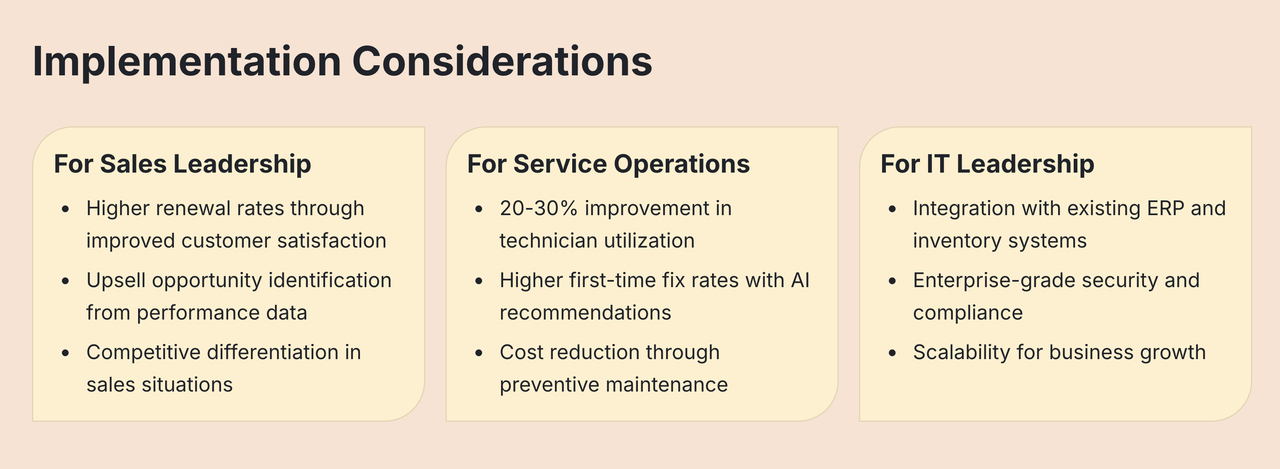

Implementation Considerations for Manufacturing Leaders

Industry Leadership Requires Action

The manufacturing field service transformation isn't a future possibility—it's happening now. Companies that wait for technology to mature further or for competitive pressure to force change will find themselves at permanent disadvantages.The convergence of AI capabilities, mobile technology maturity, and integrated platform availability means that comprehensive transformation is both technically feasible and economically practical for manufacturers of all sizes.

Experience the Future of Field Service at Fabtech 2025

Ready to see these transformative technologies in action? Join us at Fabtech 2025 from September 8-11 in Chicago to see a live demo of our AI-powered solution for field service operations.

Visit ShareCRM at Booth D37225 Location: Forming & Fabricating Section, Level 200 Max NSE

Pre-Schedule Your Demo

Book Time

Don't miss this opportunity to see how industry-leading manufacturers are transforming their field service operations from reactive to predictive. The future of manufacturing service is happening now—experience it firsthand at Fabtech 2025.

Book your 15-minute consultation today and discover why ShareCRM is the #1 B2B SaaS CRM provider trusted by 6,000+ manufacturing companies worldwide.